Company Introduction

HberTech Pile Driving Equipment Co., Ltd. is a high-tech enterprise that develops and manufactures intelligent types of equipment. The company has passed the ISO9000 quality system certification (certificate number: NOA1824367). The equipment has the characteristics of low weight, high excitation force, low noise, low wear and long life.

learn moreProduct Center

Enable your excavator to be versatile and improve investment efficiency.

Excavator Mounted Vibratory Hammers

Excavator Mounted Vibratory Hammer is driven by a hydraulic motor to generate high-speed rotation and vertical resonance excitation force.

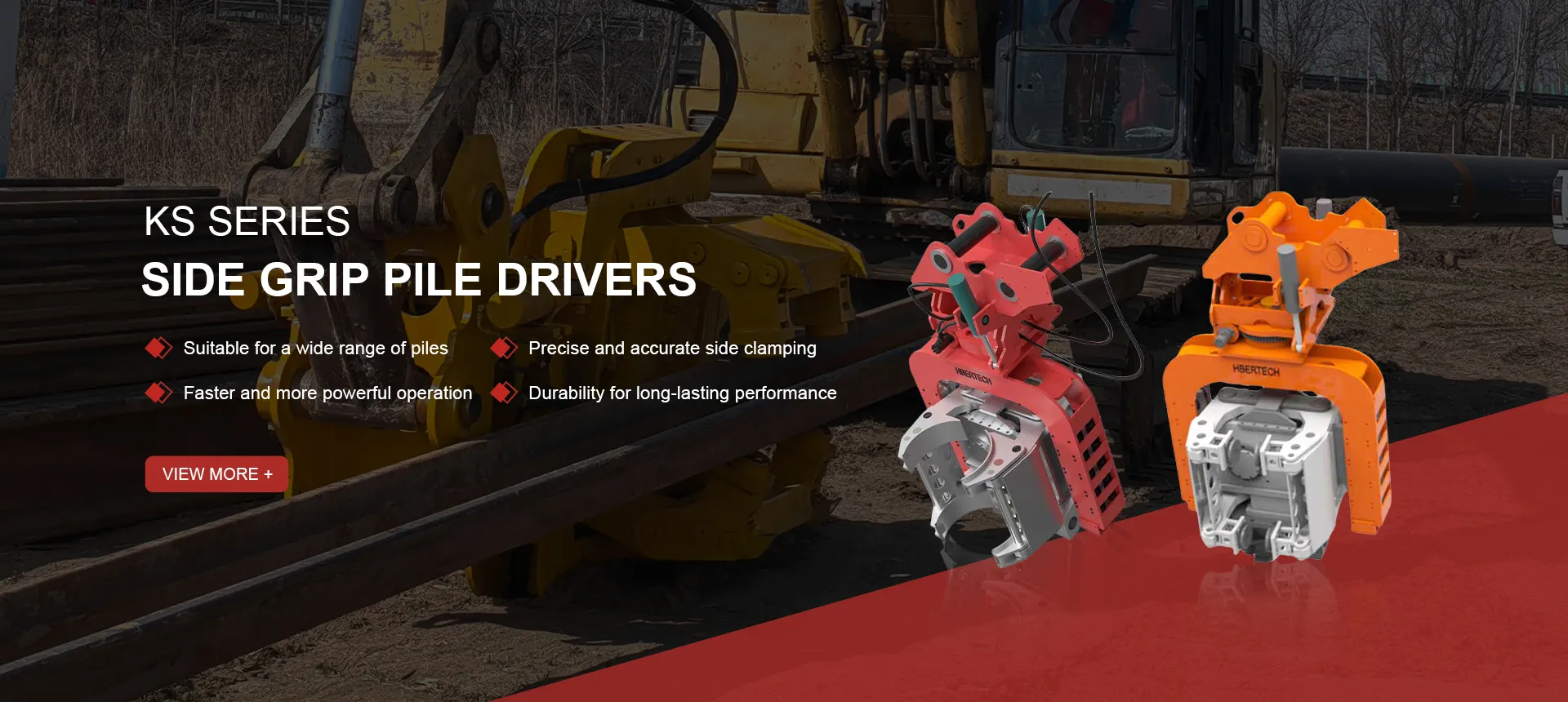

read moreRealize side clamping piles to meet the construction of limited height or extra long piles.

read moreExcavator Mounted Vibratory Hammers

High-pressure coaxial cutter suction structure, equipped with special inner profile and high-strength impeller, effectively solves the problem of blockage

read moreEngineering Case

The equipment has characteristics such as low weight, high excitation force, low noise, low wear, and high lifespan.

Application Industry

The flexible nature of operation has propelled the construction of pile foundation engineering to a new stage

Enclosure Structure

River Regulation

Waterfront Reinforcement

Traffic Engineering

Farmland Reinforcement

Piling Under the Bridge

Dredging Rivers

Do you want to contact us?

A comprehensive intelligent equipment solution provider

engaged in the R&D and manufacturing of engineering machinery

CONTACT US

The high-frequency hydraulic vibratory hammer, side grip pile driver, suction dredging pump produced by the company are specially used with excavators to give full play to the mobility of excavators.

learn moreNews and Information

Take you to learn more about the industry information of excavator working systems.

07-08-2025

How Do I Choose the Right Side Grip Pile Driver for My Project?

Choosing the right side grip pile driver for your project is critical for ensuring efficient, safe, and cost-effective pile installation. The wrong equipment can lead to underperformance, project delays, equipment damage, or even safety hazards. Because every job site has different constraints—such as soil conditions, pile types, and space limitations—your selection process should be based on a detailed evaluation of both technical requirements and site conditions.This guide outlines the key factors to consider when selecting the most suitable side grip pile driver for your construction project.1. Determine the Type and Size of PilesThe first step in selecting the right side grip pile driver is identifying the type, size, and weight of the piles you plan to install. Common pile types include:Steel sheet pilesH-beams and I-beamsPipe pilesTimber pilesVinyl or composite sheet pilesSmall precast concrete pilesConsider the following aspects:Cross-section dimensions: Ensure the clamp system is compatible with the pile profile.Pile length and weight: Heavier or longer piles require stronger gripping force and higher vibration energy.Material type: Fragile piles (like vinyl or timber) may require softer clamp pads or adjustable vibration intensity.If your project involves multiple pile types, consider a side grip unit with interchangeable clamp inserts or variable control settings.2. Match the Vibratory Force to Soil ConditionsSoil resistance is a key factor in driving performance. A side grip pile driver must deliver enough vibratory force (amplitude and frequency) to overcome soil resistance without damaging the pile.Soft soils (sand, silt, clay): Lower-frequency, higher-amplitude vibration often works best.Dense or mixed soils (gravel, hardpan, fill): Higher power and frequency may be required.Cohesive soils (stiff clay or silty clay): May require more time per pile or pre-drilling assistance.If your job site has variable soil layers, choose a pile driver with adjustable frequency and force settings, so the operator can adapt in real time.3. Evaluate the Excavator’s CompatibilitySide grip pile drivers are designed to mount on excavators. Therefore, your choice must be compatible with your existing equipment or rental fleet.Key excavator specifications to match include:Operating weight: The excavator must be heavy enough to counteract the vibration and load of the pile driver.Hydraulic flow and pressure: The side grip unit must operate within the excavator’s hydraulic system limits.Boom reach and stability: The excavator must be able to handle the pile driver and pile at full extension without tipping.Quick coupler system: Confirm compatibility for easy attachment and removal.Some manufacturers provide compatibility charts or guidance for matching side grip models to excavator classes. Always double-check specifications before committing.4. Assess Site Access and Working ConditionsThe physical layout and environment of your project site will also affect the choice of pile driver.Tight or urban job sites: Choose a compact model with a small footprint and short turning radius.Low headroom areas (under bridges or utilities): Make sure the side grip model doesn’t exceed height limitations when handling long piles.Inclined or angled pile installation: If you need to drive batter piles, select a side grip unit with tilt or rotation capabilities.Marine or wet conditions: Ensure the attachment is weather-resistant and built for high-humidity environments.If space is extremely limited, a side grip pile driver is often preferred over a top-mounted hammer or crane system due to its mobility and precision.5. Consider Driving and Extraction NeedsMany projects involve not only pile installation but also pile extraction, especially for temporary works like cofferdams, trench walls, or shoring.Choose a side grip pile driver that can:Drive piles into difficult soils without slippageExtract piles cleanly without causing damage or requiring additional equipmentApply reversible vibration for easy removalMaintain strong clamping force during both driving and pulling operationsDual-purpose units can save significant time and money by eliminating the need for separate extraction tools.6. Prioritize Control and Precision FeaturesNot all side grip pile drivers offer the same level of precision. For jobs requiring exact pile alignment or minimal vibration impact on surroundings, look for units with:360° rotation or multi-axis tilt for fine alignmentVariable vibration frequency and amplitude for adapting to different conditionsHydraulic dampening systems to reduce pile drift and misalignmentSmart control systems for load sensing, auto-clamp adjustment, or depth indicatorsThese advanced features are especially valuable on infrastructure, marine, or urban foundation projects where tolerances are strict.7. Estimate Production Rate and Project VolumeThe size and duration of your project should influence your equipment choice. For high-volume pile driving operations, you’ll need:A more powerful unit that can sustain longer working hours without overheatingFaster cycle times for loading, aligning, and driving each pileDurable materials and components that resist fatigue under repeated useIf your project is smaller or short-term, a lighter model may suffice and will be more cost-effective to purchase or rent.8. Evaluate Safety and Ergonomic ConsiderationsSafety should be built into the design of the side grip pile driver. Look for features such as:Auto-centering clamps to prevent misalignmentSecure locking systems to prevent accidental releaseShock absorption to reduce operator fatigue and machine wearClear visibility of the pile from the cab for better placement accuracyErgonomic designs not only improve safety but also increase productivity by reducing operator strain and mistakes.9. Check for Maintenance and Service RequirementsA well-chosen machine should be easy to maintain. Before finalizing your choice, consider:Availability of spare partsEase of accessing wear components (clamp pads, seals, hoses)Hydraulic system compatibility with your excavator’s servicing scheduleTechnical support or training availabilityReliable performance over the long term depends on regular maintenance. Simpler systems with robust construction often perform better on demanding jobs.10. Balance Performance with BudgetFinally, match your pile driver choice to your budget and return on investment:If the job is one-time or short-term, renting may be more economicalFor frequent or varied piling projects, buying a versatile, mid-range unit offers long-term valueDon’t overspend on capabilities you won’t need; instead, focus on reliability and performance in your specific conditionsAvoid choosing purely based on price; instead, focus on selecting the model that offers the best match to your operational needs.ConclusionSelecting the right side grip pile driver isn’t just about choosing the most powerful model—it’s about finding the best match for your pile type, site conditions, excavator setup, and production goals. A well-matched pile driver will help:Increase jobsite efficiencyReduce equipment wearImprove driving accuracyEnsure worker safetyLower overall project costsBy carefully evaluating your project’s technical requirements, environmental factors, and equipment compatibility, you can confidently choose a side grip pile driver that delivers both performance and reliability.

07-13-2025

What Are the Advantages of Using a Side Grip Pile Driver?

The side grip pile driver has emerged as a game-changing tool in the construction and foundation industry, offering a level of speed, control, and versatility that traditional pile-driving methods struggle to match. Whether working in tight urban job sites, along highways, or on marine structures, this excavator-mounted attachment provides multiple advantages that can significantly improve productivity, safety, and cost efficiency.Below are the key advantages of using a side grip pile driver:1. One-Person, One-Machine OperationOne of the most notable benefits of the side grip pile driver is that it allows a single excavator and operator to handle the entire pile-driving process:Pick up the pile from a stack (horizontally or vertically)Lift and position it using the excavator boomClamp and drive it into the groundExtract the pile if necessaryThis eliminates the need for cranes, riggers, and extra ground crews, which simplifies coordination and reduces labor costs.2. Faster Cycle TimesCompared to traditional top-mounted vibratory hammers or impact drivers, a side grip pile driver is significantly faster and more efficient:No separate lifting or handling equipment is neededAlignment is quicker due to the operator’s direct controlPiles can be driven, adjusted, and corrected with minimal effortThis speed is particularly valuable in time-sensitive projects or when working under traffic or environmental restrictions.3. Ideal for Confined SpacesSide grip pile drivers are perfect for tight, restricted, or urban job sites, where large equipment may not fit:Can work close to existing buildings, retaining walls, or utilitiesFunctions efficiently alongside roads, rail lines, or water channelsAllows vertical or angled pile driving even in narrow work zonesTheir compact profile and flexible boom-mounted positioning give them a major edge over traditional pile-driving rigs.4. Improved Safety on SiteBy reducing the number of workers required and minimizing manual pile handling, side grip pile drivers enhance site safety:No need for workers to stand near or under suspended loadsReduced interaction between crew members and moving machineryOperator remains safely in the cab during the entire processAdditionally, the precise control of the machine minimizes the risk of pile misalignment, slippage, or accidental damage.5. Greater Precision and ControlBecause the operator can rotate, tilt, and position the hammer with the excavator’s boom, side grip pile drivers provide excellent accuracy in:Aligning piles vertically or at the correct angleAdjusting position mid-drive to compensate for soil variationPlacing piles exactly along layout lines without manual repositioningThis level of precision is difficult to achieve with crane-suspended hammers or top-mount-only systems.6. Dual Functionality: Driving and ExtractingSide grip pile drivers are capable not only of installing piles but also removing them. This makes them ideal for:Temporary retaining wallsSheet pile shoring in excavationsTemporary bridge supports or cofferdamsInstead of mobilizing separate equipment for extraction, the same tool can remove piles quickly and efficiently by reversing the vibration direction and using hydraulic clamp force.7. Reduced Noise and Vibration ImpactIn comparison to impact hammers, side grip vibratory hammers produce less noise and ground vibration, making them more suitable for:Urban construction sitesProjects near sensitive infrastructure (e.g., utilities, pipelines)Environmental zones or protected areasThis is especially important where local ordinances restrict noise levels or where adjacent structures are vulnerable to vibration damage.8. Minimal Setup and Transport RequirementsBecause the side grip pile driver is mounted on a standard excavator, it is:Easy to transport between job sites without special permitsQuick to set up with minimal assembly or riggingSimple to switch between different attachments if neededThis makes it ideal for contractors handling multiple small to medium-scale projects with limited mobilization time.9. Compatibility with Various Pile TypesSide grip pile drivers can handle a wide range of pile materials and shapes, including:Steel sheet pilesH-beams and I-beamsTimber pilesPipe piles (steel or concrete)Vinyl and composite pilesWith the appropriate clamp inserts or adjustments, it can grip and drive different types of piles efficiently.10. Lower Operating CostsDue to reduced labor, faster installation, and fewer auxiliary machines, the overall cost of operation with a side grip pile driver is lower than with traditional methods. Additional cost savings come from:Less fuel consumption (fewer machines running)Fewer equipment rentalsReduced downtime from pile misalignment or equipment repositioningOver the course of a project, these savings can be substantial.11. Rapid Learning Curve and Operator EfficiencyMost excavator operators can quickly adapt to operating a side grip pile driver. The controls are typically intuitive and similar to other hydraulic attachments, which means:Less training time is requiredFewer errors due to unfamiliarityHigh productivity is achievable even with smaller crewsFor contractors, this reduces onboarding costs and improves crew flexibility.12. Efficient for Both Temporary and Permanent StructuresBecause it handles both installation and extraction, the side grip pile driver is well-suited for:Temporary works like excavation shoringPermanent installations such as retaining walls, foundations, and marine wallsEmergency repairs or replacement of existing pilesIts versatility makes it a valuable asset across multiple construction scenarios.ConclusionThe side grip pile driver offers a combination of speed, control, and operational flexibility that makes it one of the most efficient tools for modern pile-driving work—especially in tight, complex, or sensitive environments. With its ability to drive, reposition, and extract piles using only an excavator, it significantly reduces labor, equipment costs, and project time.Key advantages include:Faster, safer, and more accurate operationExcellent performance in confined or urban spacesVersatility across pile types and project scopesLower total operating and transport costsFor contractors seeking efficient foundation and support solutions, the side grip pile driver is a smart, forward-thinking choice.

READ MOREThe side grip pile driver has emerged as a game-changing tool in the construction and foundation industry, offering a level of speed, control, and versatility that traditional pile-driving methods struggle to match. Whether working in tight urban job sites, along highways, or on marine structures, this excavator-mounted attachment provides multiple advantages that can significantly improve productivity, safety, and cost efficiency.Below are the key advantages of using a side grip pile driver:1. One-Person, One-Machine OperationOne of the most notable benefits of the side grip pile driver is that it allows a single excavator and operator to handle the entire pile-driving process:Pick up the pile from a stack (horizontally or vertically)Lift and position it using the excavator boomClamp and drive it into the groundExtract the pile if necessaryThis eliminates the need for cranes, riggers, and extra ground crews, which simplifies coordination and reduces labor costs.2. Faster Cycle TimesCompared to traditional top-mounted vibratory hammers or impact drivers, a side grip pile driver is significantly faster and more efficient:No separate lifting or handling equipment is neededAlignment is quicker due to the operator’s direct controlPiles can be driven, adjusted, and corrected with minimal effortThis speed is particularly valuable in time-sensitive projects or when working under traffic or environmental restrictions.3. Ideal for Confined SpacesSide grip pile drivers are perfect for tight, restricted, or urban job sites, where large equipment may not fit:Can work close to existing buildings, retaining walls, or utilitiesFunctions efficiently alongside roads, rail lines, or water channelsAllows vertical or angled pile driving even in narrow work zonesTheir compact profile and flexible boom-mounted positioning give them a major edge over traditional pile-driving rigs.4. Improved Safety on SiteBy reducing the number of workers required and minimizing manual pile handling, side grip pile drivers enhance site safety:No need for workers to stand near or under suspended loadsReduced interaction between crew members and moving machineryOperator remains safely in the cab during the entire processAdditionally, the precise control of the machine minimizes the risk of pile misalignment, slippage, or accidental damage.5. Greater Precision and ControlBecause the operator can rotate, tilt, and position the hammer with the excavator’s boom, side grip pile drivers provide excellent accuracy in:Aligning piles vertically or at the correct angleAdjusting position mid-drive to compensate for soil variationPlacing piles exactly along layout lines without manual repositioningThis level of precision is difficult to achieve with crane-suspended hammers or top-mount-only systems.6. Dual Functionality: Driving and ExtractingSide grip pile drivers are capable not only of installing piles but also removing them. This makes them ideal for:Temporary retaining wallsSheet pile shoring in excavationsTemporary bridge supports or cofferdamsInstead of mobilizing separate equipment for extraction, the same tool can remove piles quickly and efficiently by reversing the vibration direction and using hydraulic clamp force.7. Reduced Noise and Vibration ImpactIn comparison to impact hammers, side grip vibratory hammers produce less noise and ground vibration, making them more suitable for:Urban construction sitesProjects near sensitive infrastructure (e.g., utilities, pipelines)Environmental zones or protected areasThis is especially important where local ordinances restrict noise levels or where adjacent structures are vulnerable to vibration damage.8. Minimal Setup and Transport RequirementsBecause the side grip pile driver is mounted on a standard excavator, it is:Easy to transport between job sites without special permitsQuick to set up with minimal assembly or riggingSimple to switch between different attachments if neededThis makes it ideal for contractors handling multiple small to medium-scale projects with limited mobilization time.9. Compatibility with Various Pile TypesSide grip pile drivers can handle a wide range of pile materials and shapes, including:Steel sheet pilesH-beams and I-beamsTimber pilesPipe piles (steel or concrete)Vinyl and composite pilesWith the appropriate clamp inserts or adjustments, it can grip and drive different types of piles efficiently.10. Lower Operating CostsDue to reduced labor, faster installation, and fewer auxiliary machines, the overall cost of operation with a side grip pile driver is lower than with traditional methods. Additional cost savings come from:Less fuel consumption (fewer machines running)Fewer equipment rentalsReduced downtime from pile misalignment or equipment repositioningOver the course of a project, these savings can be substantial.11. Rapid Learning Curve and Operator EfficiencyMost excavator operators can quickly adapt to operating a side grip pile driver. The controls are typically intuitive and similar to other hydraulic attachments, which means:Less training time is requiredFewer errors due to unfamiliarityHigh productivity is achievable even with smaller crewsFor contractors, this reduces onboarding costs and improves crew flexibility.12. Efficient for Both Temporary and Permanent StructuresBecause it handles both installation and extraction, the side grip pile driver is well-suited for:Temporary works like excavation shoringPermanent installations such as retaining walls, foundations, and marine wallsEmergency repairs or replacement of existing pilesIts versatility makes it a valuable asset across multiple construction scenarios.ConclusionThe side grip pile driver offers a combination of speed, control, and operational flexibility that makes it one of the most efficient tools for modern pile-driving work—especially in tight, complex, or sensitive environments. With its ability to drive, reposition, and extract piles using only an excavator, it significantly reduces labor, equipment costs, and project time.Key advantages include:Faster, safer, and more accurate operationExcellent performance in confined or urban spacesVersatility across pile types and project scopesLower total operating and transport costsFor contractors seeking efficient foundation and support solutions, the side grip pile driver is a smart, forward-thinking choice.

07-15-2025

Can an Excavator Mounted Vibratory Hammer Be Used in Urban Areas?

An excavator mounted vibratory hammer can be used effectively in urban areas, but there are important considerations and precautions to ensure the operation is safe, efficient, and minimally disruptive to the surrounding environment. Urban construction sites often present unique challenges such as limited space, nearby structures, noise restrictions, and public safety concerns.This article explores how vibratory hammers can be applied in urban settings, the benefits they offer, and the key factors to consider for successful use.Advantages of Using Vibratory Hammers in Urban AreasReduced Noise and Vibration Compared to Impact HammersUnlike traditional impact hammers, which generate loud repeated blows, vibratory hammers use high-frequency vibrations to drive piles. This results in:Lower noise levels, making them more suitable near residential or commercial buildingsReduced ground vibrations, minimizing the risk of damage to nearby structures or underground utilitiesCompact and Maneuverable EquipmentBecause the vibratory hammer is mounted on an excavator, it benefits from the excavator’s mobility and compact footprint. This allows it to:Operate in tight spaces where larger pile-driving rigs cannot fitEasily maneuver around obstacles such as roads, sidewalks, and utilitiesBe quickly relocated within the site to different pile positionsPrecision and ControlModern vibratory hammers often allow for adjustable frequency and amplitude settings. This means:Operators can fine-tune the vibration intensity to suit sensitive urban soil conditionsThe hammer can be stopped immediately if unusual resistance or vibrations occur, protecting adjacent structuresKey Considerations for Using Vibratory Hammers in Urban AreasNoise and Vibration RegulationsUrban construction sites are subject to strict noise and vibration limits imposed by local authorities. Before starting work:Review municipal regulations on permissible noise levels and working hoursConduct baseline vibration monitoring to assess existing conditionsImplement noise mitigation measures such as acoustic barriers or scheduling work during less sensitive hoursSite Access and Space ConstraintsUrban sites often have limited access routes and tight working spaces. To address this:Choose an excavator and vibratory hammer combination sized appropriately for the sitePlan material deliveries and pile staging carefully to minimize traffic disruptionsUse compact vibratory hammers designed for small excavators or mini-excavators if necessaryProtection of Adjacent Structures and UtilitiesDriving piles in close proximity to existing buildings, roads, or underground utilities requires extra caution:Conduct thorough site investigations, including utility mapping and structural surveysUse vibration monitoring devices during pile driving to detect excessive ground movementAdjust vibration frequency and amplitude to reduce impact on sensitive areasConsider pre-drilling or alternative foundation methods if conditions are too riskyPublic and Worker SafetyWith pedestrians and vehicles nearby, it is essential to:Establish clear safety zones and barriers around the operation areaPost warning signs and use flaggers or traffic control where necessaryEnsure operators maintain full situational awareness and communication with ground personnelEnvironmental ImpactUrban projects must manage dust, emissions, and waste responsibly. Vibratory hammers contribute positively by:Minimizing dust generation compared to impact drivingReducing fuel consumption due to faster pile installation timesEnabling quieter operations that reduce community disturbancePractical Examples of Urban ApplicationsFoundation Work for High-Rise BuildingsVibratory hammers can install sheet piles or H-beams quickly for basement walls and deep foundations without causing excessive noise or vibration.Retaining Walls and Excavation SupportIn narrow urban lots, compact vibratory hammers support excavation shoring while fitting within tight spaces.Infrastructure UpgradesRoad widening, bridge repairs, or utility vault installations often benefit from the mobility and reduced disturbance of vibratory pile driving.Limitations and When to Consider AlternativesWhile vibratory hammers are well-suited for many urban projects, there are cases where they may be less effective or inappropriate:Very Dense or Rocky Soil LayersVibratory hammers may struggle to drive piles through hard layers; impact or hydraulic hammers might be necessary.Extremely Sensitive Historic BuildingsIn some cases, even low vibration might risk damage, requiring alternative foundation methods such as drilled shafts or micro-piles.Nighttime or Noise-Sensitive AreasEven quieter vibratory hammers might not meet strict curfew requirements, necessitating work scheduling adjustments.ConclusionAn excavator mounted vibratory hammer is a versatile and practical tool for pile driving in urban areas, offering significant advantages in terms of noise reduction, operational flexibility, and precision. By carefully considering site-specific factors like regulations, space, soil conditions, and safety, contractors can leverage this equipment to achieve efficient foundation work with minimal disruption.Successful urban use of vibratory hammers relies on thorough planning, communication with stakeholders, and adherence to safety and environmental guidelines—making it a reliable choice for modern city construction projects.

READ MOREAn excavator mounted vibratory hammer can be used effectively in urban areas, but there are important considerations and precautions to ensure the operation is safe, efficient, and minimally disruptive to the surrounding environment. Urban construction sites often present unique challenges such as limited space, nearby structures, noise restrictions, and public safety concerns.This article explores how vibratory hammers can be applied in urban settings, the benefits they offer, and the key factors to consider for successful use.Advantages of Using Vibratory Hammers in Urban AreasReduced Noise and Vibration Compared to Impact HammersUnlike traditional impact hammers, which generate loud repeated blows, vibratory hammers use high-frequency vibrations to drive piles. This results in:Lower noise levels, making them more suitable near residential or commercial buildingsReduced ground vibrations, minimizing the risk of damage to nearby structures or underground utilitiesCompact and Maneuverable EquipmentBecause the vibratory hammer is mounted on an excavator, it benefits from the excavator’s mobility and compact footprint. This allows it to:Operate in tight spaces where larger pile-driving rigs cannot fitEasily maneuver around obstacles such as roads, sidewalks, and utilitiesBe quickly relocated within the site to different pile positionsPrecision and ControlModern vibratory hammers often allow for adjustable frequency and amplitude settings. This means:Operators can fine-tune the vibration intensity to suit sensitive urban soil conditionsThe hammer can be stopped immediately if unusual resistance or vibrations occur, protecting adjacent structuresKey Considerations for Using Vibratory Hammers in Urban AreasNoise and Vibration RegulationsUrban construction sites are subject to strict noise and vibration limits imposed by local authorities. Before starting work:Review municipal regulations on permissible noise levels and working hoursConduct baseline vibration monitoring to assess existing conditionsImplement noise mitigation measures such as acoustic barriers or scheduling work during less sensitive hoursSite Access and Space ConstraintsUrban sites often have limited access routes and tight working spaces. To address this:Choose an excavator and vibratory hammer combination sized appropriately for the sitePlan material deliveries and pile staging carefully to minimize traffic disruptionsUse compact vibratory hammers designed for small excavators or mini-excavators if necessaryProtection of Adjacent Structures and UtilitiesDriving piles in close proximity to existing buildings, roads, or underground utilities requires extra caution:Conduct thorough site investigations, including utility mapping and structural surveysUse vibration monitoring devices during pile driving to detect excessive ground movementAdjust vibration frequency and amplitude to reduce impact on sensitive areasConsider pre-drilling or alternative foundation methods if conditions are too riskyPublic and Worker SafetyWith pedestrians and vehicles nearby, it is essential to:Establish clear safety zones and barriers around the operation areaPost warning signs and use flaggers or traffic control where necessaryEnsure operators maintain full situational awareness and communication with ground personnelEnvironmental ImpactUrban projects must manage dust, emissions, and waste responsibly. Vibratory hammers contribute positively by:Minimizing dust generation compared to impact drivingReducing fuel consumption due to faster pile installation timesEnabling quieter operations that reduce community disturbancePractical Examples of Urban ApplicationsFoundation Work for High-Rise BuildingsVibratory hammers can install sheet piles or H-beams quickly for basement walls and deep foundations without causing excessive noise or vibration.Retaining Walls and Excavation SupportIn narrow urban lots, compact vibratory hammers support excavation shoring while fitting within tight spaces.Infrastructure UpgradesRoad widening, bridge repairs, or utility vault installations often benefit from the mobility and reduced disturbance of vibratory pile driving.Limitations and When to Consider AlternativesWhile vibratory hammers are well-suited for many urban projects, there are cases where they may be less effective or inappropriate:Very Dense or Rocky Soil LayersVibratory hammers may struggle to drive piles through hard layers; impact or hydraulic hammers might be necessary.Extremely Sensitive Historic BuildingsIn some cases, even low vibration might risk damage, requiring alternative foundation methods such as drilled shafts or micro-piles.Nighttime or Noise-Sensitive AreasEven quieter vibratory hammers might not meet strict curfew requirements, necessitating work scheduling adjustments.ConclusionAn excavator mounted vibratory hammer is a versatile and practical tool for pile driving in urban areas, offering significant advantages in terms of noise reduction, operational flexibility, and precision. By carefully considering site-specific factors like regulations, space, soil conditions, and safety, contractors can leverage this equipment to achieve efficient foundation work with minimal disruption.Successful urban use of vibratory hammers relies on thorough planning, communication with stakeholders, and adherence to safety and environmental guidelines—making it a reliable choice for modern city construction projects.

-2.webp?x-oss-process=image/resize)

-2.webp?x-oss-process=image/resize)