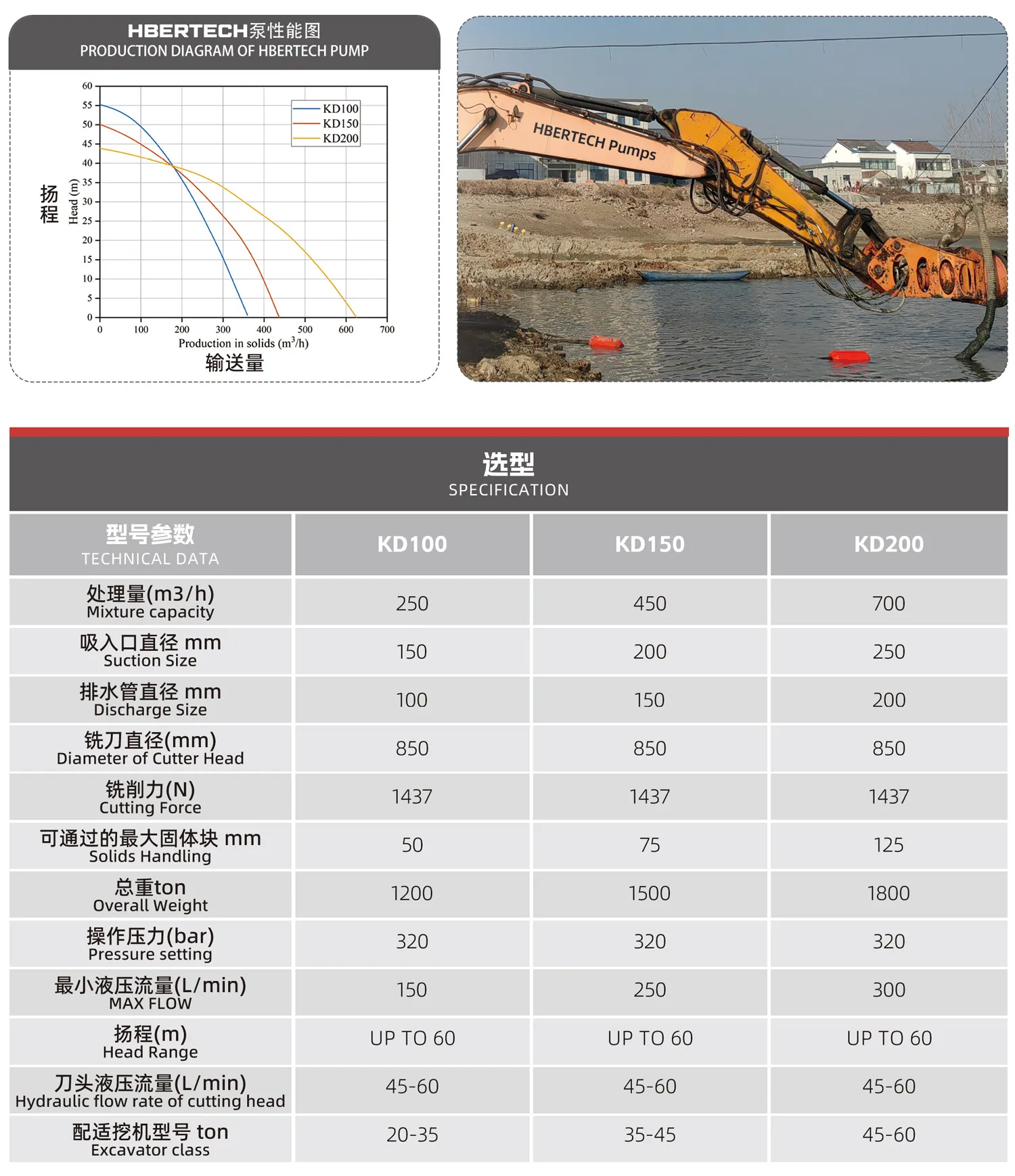

Hydraulic Dredge Pump KD150

Special inner type and high-strength impeller solve clog effectively.

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

Excavator Dredge Pump Attachment,as a large dredging equipment,is able to work continuously for a long time, and it is less affected by the weather and water level of the river, so it is able to excavate continuously and has high engineering efficiency.

※ Product Benefits

High Throughput

The pump casing flow channel is designed for a solids throughput of 40-70%,improving the passage rate of sludge and large foreign objects.

Long-Distance Transport

Driven by a coaxial high-flow hydraulic motor,enabling high-lift transportation.

Customized Agitator Head

Equipped with a wear-resistant alloy cutter head and a high-torque planetary motor,significantly enhancing crushing capability.

Visualization

The dredging process can be displayed tracked,and its duration forecasted.

※ Product Features

1. Direct drive to the excavator, flexible movement

The pump is installed on the boom or bucket position of the excavator through a standard flange, without the need for an additional pump ship or power station. The movement of the excavator means the movement of the pump body, which can easily cope with areas that are difficult for traditional equipment to enter, such as shoals, shores, and complex terrain, and significantly expand the scope of operation.

2. High wear-resistant design, long service life

The flow-through parts of the pump body are made of high-chromium alloy, wear-resistant steel or ceramic materials, which can effectively resist the wear of high-concentration mud, gravel, slurry and other media on the pump cavity, extend the service life of the equipment, and reduce the maintenance frequency.

3. Large flow, high head, leading efficiency

This type of pump adopts an advanced impeller structure design, the suction concentration can reach more than 60%, the particle passing diameter is large, the flow range is wide, and the head is moderate (generally 10-35 meters), which meets the requirements of various high-load and high-viscosity media transportation and adapts to a variety of complex working conditions.

4. Supports multiple mixing devices and adapts to multiple media

Optional accessories such as hydraulic agitator, cutting head, reamer, jet flushing system, etc. can be used to enhance the silt stirring capacity, which is particularly suitable for the pumping and drainage of composite media such as clay soil, water plants, plastic garbage, industrial waste, etc.

5. Simple operation and convenient maintenance

The equipment can be controlled by the excavator operator only, without the need for additional crew members or pump operators. The pump body has a compact structure and a reasonable location for maintenance ports, which makes it easy to clean and replace wearing parts. The standard accessories are highly versatile and more convenient for after-sales maintenance.

※ Application Areas

River and lake dredging: remove sedimentary silt, improve river navigation and flood storage capacity, and improve water environment;

Port and dock sediment cleaning: clean berth sediments to ensure safe berthing of ships;

Sand mining and resource recovery: river or seabed sand mining operations, which can be continuously sucked and transported to the screening system;

Tailing pond slag discharge: discharge and reuse of slag slurry at the bottom of mine tailings pond;

Municipal sewage pool/sand settling tank cleaning: suck silt and solid particles deposited in urban sewage stations;

Environmental protection projects: dredging of polluted water bodies, black and smelly rivers, and industrial waste liquid pools.

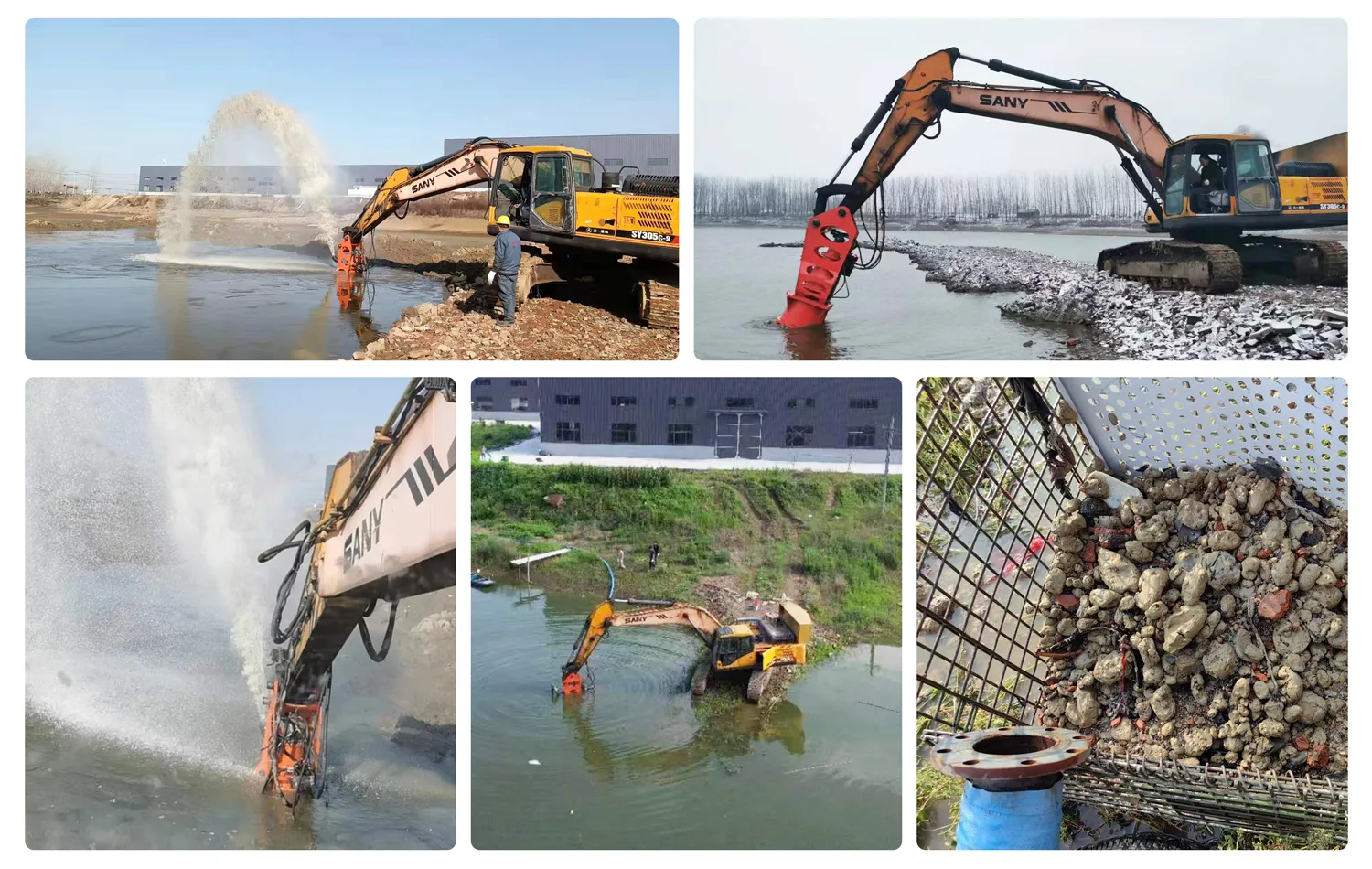

※ Construction Site

HberTech Pile Driving Equipment Co., Ltd. is a high-tech enterprise that develops and manufactures intelligent types of equipment. The company has passed the ISO9000 quality system certification (certificate number: NOA1824367). The equipment has the characteristics of low weight, high excitation force, low noise, low wear and long life.

Excavator Mounted Vibratory Hammers, Side Grip Vibro Hammers and Excavator Dredge Pump Attachment produced by us are mobile and flexible. The foundation construction has entered a new stage which significantly saves construction costs and improves work efficiency. The developed products have obtained several invention patents.

-2.webp?x-oss-process=image/resize)

-2.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)

.webp?x-oss-process=image/resize)